BRIMFLEXä TUBINGS & SLEEVINGS

BRIMFLEXä B105 PVC TUBINGS—MIL-I-631

BRIMFLEXä

TUBINGS & SLEEVINGS

BRIMFLEXä

B105 PVC TUBINGS—MIL-I-631

BRIMFLEXä

PVC tubings are extruded from non-migrating Polyvinylchloride (PVC) resin

for sup-

erior all-around performance.

Meets MIL-I-631D Type F, Form U, Grades A & C, Class 1 & 2, Cat.1.,

ASTM-D-876 & ASTM-D-922.

This tubings is non-flammable, and UL recognized* (meets the UL VW-1

vertical wire flame test requirements).

It is resistant to most oils, heat, chemical corrosion, water,

fungus, aging, and has a high abrasion

resistance. It is designed for electrical, electronic and air-

craft applications. It retains

it's flexibility, permitting it to cling and protect irregularly shaped

objects, components, etc. It

snakes well under practically all conditions. Dielectric Strength:

.020" wall--800V/Mil. Shore

A Durometer: Clear 90, Colors: 95. OPER. TEMP.: -30°C

to +105°C

| Brimflexä No. |

Size | Nom. I.D. |

Nom. Wall |

± Wall Toler. |

M.M. | Std. P-U |

Brimflexä No. |

Size | Nom. I.D. |

Nom. Wall |

±Wall Toler. |

M.M. | Std. P-U |

|

| B105-24 | 24 | .022" | .012" | .002" | 0.56 | 1 | B105-2 | 2 | .263" | .020" | .003" | 6.69 | 1 | |

| B105-22 | 22 | .027" | .012" | .002" | 0.69 | 1 | B105-1 | 1 | .294" | .020" | .003" | 7.50 | 1 | |

| B105-20 | 20 | .034" | .016" | .003" | 0.86 | 1 | B105-5/16" | 5/16" | .312" | .025" | .003" | 7.93 | 3 | |

| B105-19 | 19 | .038" | .016" | .003" | 0.97 | 1 | B105-0 | 0 | .330" | .025" | .003" | 8.38 | 3 | |

| B105-18 | 18 | .042" | .016" | .003" | 1.06 | 1 | B105-3/8" | 3/8" | .375" | .025" | .003" | 9.52 | 3 | |

| B105-17 | 17 | .047" | .016" | .003" | 1.19 | 1 | B105-7/16" | 7/16" | .438" | .025" | .003" | 11.12 | 3 | |

| B105-16 | 16 | .053" | .016" | .003" | 1.35 | 1 | B105-1/2" | 1/2" | .500" | .025" | .003" | 12.70 | 3 | |

| B105-15 | 15 | .059" | .016" | .003" | 1.50 | 1 | B105-9/16" | 9/16" | .562" | .025" | .003" | 14.28 | 3 | |

| B105-14 | 14 | .066" | .016" | .003" | 1.68 | 1 | B105-5/8" | 5/8" | .625" | .030" | .005" | 15.87 | 4 | |

| B105-13 | 13 | .076" | .016" | .003" | 1.93 | 1 | B105-3/4" | 3/4" | .750" | .035" | .005" | 19.05 | 4 | |

| B105-12 | 12 | .085" | .016" | .003" | 2.16 | 1 | B105-7/8" | 7/8" | .875" | .035" | .005" | 22.22 | 5 | |

| B105-11 | 11 | .095" | .016" | .003" | 2.41 | 1 | B105-1" | 1" | 1.000" | .035" | .005" | 25.40 | 5 | |

| B105-10 | 10 | .106" | .016" | .003" | 2.69 | 1 | B105-1 1/8" | 1 1/8" | 1.125" | .035" | .005" | 28.57 | 5 | |

| B105-9 | 9 | .118" | .020" | .003" | 3.00 | 1 | B105-1 1/4" | 1 1/4" | 1.250" | .040" | .005" | 31.79 | 5 | |

| B105-8 | 8 | .133" | .020" | .003" | 3.44 | 1 | B105-1 3/8" | 1 3/8" | 1.375" | .045" | .005" | 34.92 | 5 | |

| B105-7 | 7 | .148" | .020" | .003" | 3.79 | 1 | B105-1 1/2" | 1 1/2" | 1.500" | .045" | .006" | 38.10 | 5 | |

| B105-6 | 6 | .166" | .020" | .003" | 4.23 | 1 | B105-1 3/4" | 1 3/4" | 1.750" | .055" | .008" | 44.45 | 5 | |

| B105-5 | 5 | .186" | .020" | .003" | 4.73 | 1 | B105-2" | 2" | 2.000" | .060" | .010" | 50.80 | 5 | |

| B105-4 | 4 | .208" | .020" | .003" | 5.83 | 1 | B105-2 1/4" | 2 1/4" | 2.250" | .065" | .010" | 57.15 | 5 | |

| B105-3 | 3 | .234" | .020" | .003" | 5.95 | 1 | B105-2 1/2" | 2 1/2" | 2.500" | .070" | .010" | 63.50 | 5 | |

| B105-1/4" | 1/4" | .250" | .020" | .003" | 6.35 | 2 |

STD. P-U: 1) 100',500',1000' 2) 500',1000'

3) 100',250',500' 4) 50',100',250'

5) 25',50',100'

STD. COLORS: Black,White,Red,Clear. If no

color is specified, we ship Black.

UL recognized versions are run to order.

OTHER COLORS ARE AVAILABLE TO ORDER.

B110 tubings meet MIL-I-631 except

for its heavy (.032") wall. Suitable for those situations where

an

inexpensive, general all-purpose, flexible,

yet abrassion resistant tubing is required. It's heavier wall

provides extra mechanical strength/protection

than that provided by standard MIL-I-631 tubing. B110

meets UL VW-1 requirements, is made

from a non-migrating PVC resin for superior all around perfor-

mance. Resistant to oils, heat,

chemical corrosion, water, fungus and aging. It is ideal for electrical,

electronic & aircraft applications.

OPER. TEMP.: -30°C

to +105°C.

| Brimflexä No. |

Size | Nom. I.D. |

Nom. Wall |

M.M. | STD. P-U |

Brimflexä No. |

Size | Nom. I.D. |

Nom. Wall |

M.M. | STD. P-U |

||

| B110-24 | 24 | .022" | .032" | 0.56 | 1000' | B110-8 | 8 | .133" | .032" | 3.44 | 500' | ||

| B110-22 | 22 | .027" | .032" | 0.69 | 1000' | B110-7 | 7 | .148" | .032" | 3.79 | 500' | ||

| B110-20 | 20 | .034" | .032" | 0.86 | 1000' | B110-6 | 6 | .166" | .032" | 4.23 | 500' | ||

| B110-19 | 19 | .038" | .032" | 0.97 | 1000' | B110-5 | 5 | .186" | .032" | 4.73 | 500' | ||

| B110-18 | 18 | .042" | .032" | 1.06 | 1000' | B110-4 | 4 | .208" | .032" | 5.28 | 500' | ||

| B110-17 | 17 | .047" | .032" | 1.19 | 1000' | B110-3 | 3 | .234" | .032" | 5.95 | 500' | ||

| B110-16 | 16 | .053" | .032" | 1.35 | 1000' | B110-1/4" | 1/4" | .250" | .032" | 6.35 | 500' | ||

| B110-15 | 15 | .059" | .032" | 1.50 | 1000' | B110-2 | 2 | .263" | .032" | 6.69 | 500' | ||

| B110-14 | 14 | .066" | .032" | 1.68 | 1000' | B110-1 | 1 | .294" | .032" | 7.50 | 500' | ||

| B110-13 | 13 | .076" | .032" | 1.93 | 1000' | B110-5/16" | 5/16" | .312" | .032" | 7.93 | 500' | ||

| B110-12 | 12 | .085" | .032" | 2.16 | 1000' | B110-0 | 0 | .330" | .032" | 8.38 | 500' | ||

| B110-11 | 11 | .095" | .032" | 2.41 | 1000' | B110-3/8" | 3/8" | .375" | .032" | 9.52 | 500' | ||

| B110-10 | 10 | .106" | .032" | 2.69 | 1000' | B110-7/16" | 7/16" | .438" | .032" | 11.12 | 500' | ||

| B110-9 | 9 | .118" | .032" | 3.00 | 1000' | B110-1/2" | 1/2" | .500" | .032" | 12.70 | 250' |

STD. COLORS: Black,Clear. If no color is

specified, we ship Black.

Low temperature PVC tubings per MIL-I-7444 Ty. I &

III Cl. 2 is available to order.

BRIMFLEXä

BSR SILICONE RUBBER TUBING—

MIL-R-5847 & ZZ-R-765 -- 200°C

BRIMFLEXä

BSR Silicone Rubber tubing is an extremely elastic and stable high temperature

& low

temperature tubing. Besides being

extremely flexible, it has excellent mechanical strength (tear

resistance) tensile strength, elongation,

and weather resistance), and outstanding dielectric strengh

and corona resistance. BSR meets

MIL-R-5847 and Fed Spec. ZZ-R-765/9, Class 2b.

OPER. VOLT. 28AWG to 5/8": 300V; 3/4"

to 1: 600V. STD COLOR: WHITE

| Brimlflexä No. |

Size | Nom. I.D. |

Nom. Wall |

Std. P-U |

Brimlflexä No. |

Size | Nom. I.D. |

Nom. Wall |

Std. P-U |

||

| BSR-28 | 28 | .015" | .016" | 1000' | BSR-8 | 8 | .133" | .020" | 500' | ||

| BSR-26 | 26 | .018" | .016" | 1000' | BSR-7 | 7 | .148" | .020" | 500' | ||

| BSR-24 | 24 | .022" | .016" | 1000' | BSR-6 | 6 | .166" | .020" | 250' | ||

| BSR-22 | 22 | .027" | .016" | 1000' | BSR-5 | 5 | .186" | .020" | 250' | ||

| BSR-20 | 20 | .034" | .016" | 1000' | BSR-4 | 4 | .208" | .035" | 250' | ||

| BSR-19 | 19 | .038" | .016" | 1000' | BSR-3 | 3 | .233" | .035" | 250' | ||

| BSR-18 | 18 | .042" | .016" | 1000' | BSR-2 | 2 | .262" | .035" | 250' | ||

| BSR-17 | 17 | .047" | .016" | 1000' | BSR-1 | 1 | .294" | .035" | 250' | ||

| BSR-16 | 16 | .053" | .016" | 1000' | BSR-0 | 0 | .329" | .035" | 250' | ||

| BSR-15 | 15 | .059" | .016" | 500' | BSR-3/8" | 3/8" | .382" | .035" | 250' | ||

| BSR-14 | 14 | .066" | .016" | 500' | BSR-7/16" | 7/16" | .446" | .035" | 250' | ||

| BSR-13 | 13 | .076" | .016" | 500' | BSR-1/2" | 1/2" | .508" | .035" | 100' | ||

| BSR-12 | 12 | .085" | .016" | 500' | BSR-5/8" | 5/8" | .636" | .040" | 100' | ||

| BSR-11 | 11 | .095" | .016" | 500' | BSR-3/4" | 3/4" | .760" | .060" | 100' | ||

| BSR-10 | 10 | .106" | .016" | 500' | BSR-7/8" | 7/8" | .895" | .070" | 100' | ||

| BSR-9 | 9 | .118" | .020" | 500' | BSR-1" | 1" | 1.010" | .080" | 100' |

BRIMFLEXä

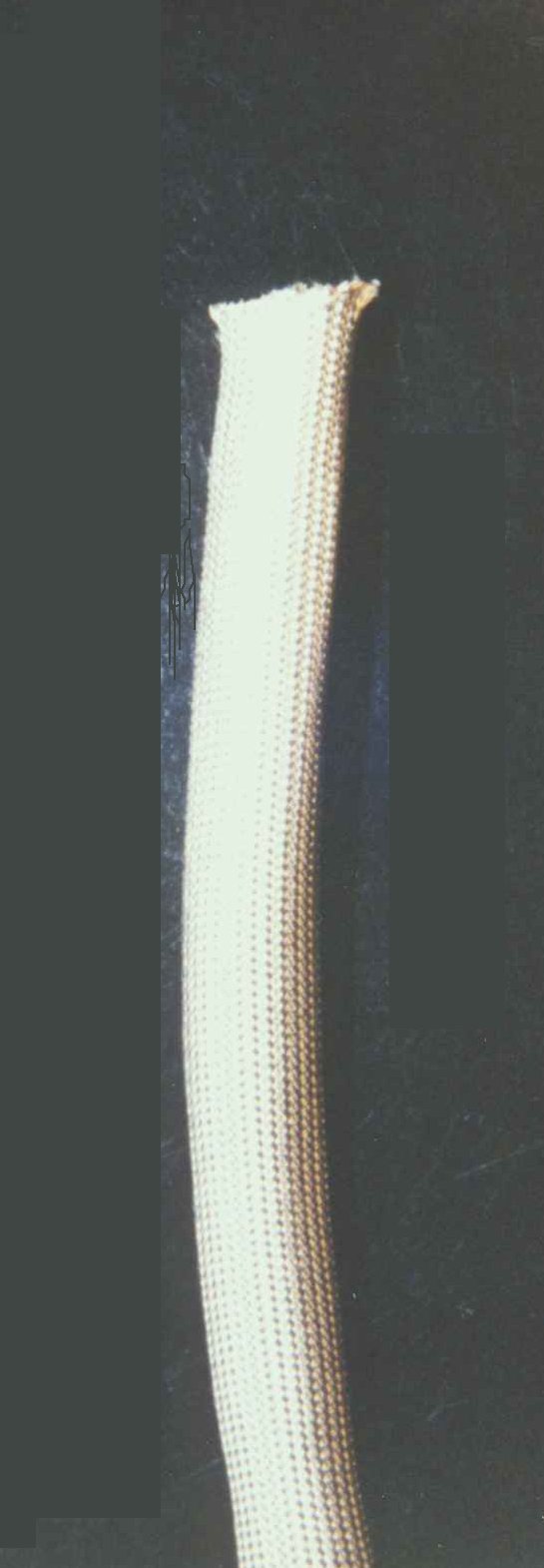

BFG fiberglass sleeving is a commercial tightly braided heat treated fiberglass

sleeving

that is very flexible, and used for

high temperature applications--up to 1200°F.

BFG fiberglass is non-

flamable and treated to remove all

organic matter. BFG conforms to NEMA Spec. VSI, Class H (240°C)

Dielectric Strength is determined by

space factor. Low-fraying. Std. Color: Natural/White.

OPER.TEMP.: 1200°F.

| Brimlflexä No. |

Size | Nom. I.D. |

Nom. Wall |

Std. P-U | Brimlflexä No. |

Size | Nom. I.D. |

Nom. Wall |

Std. P-U | ||

| BFG-24 | 24 | .022" | .010" | 100',1000' | BFG-6 | 6 | .166" | .015" | 100',250' | ||

| BFG-22 | 22 | .027" | .010" | 100',1000' | BFG-5 | 5 | .186" | .015" | 100',250' | ||

| BFG-20 | 20 | .034" | .010" | 100',1000' | BFG-4 | 4 | .208" | .015" | 100',250' | ||

| BFG-18 | 18 | .042" | .010" | 100',1000' | BFG-3 | 3 | .234" | .015" | 100',250' | ||

| BFG-17 | 17 | .047" | .010" | 100',1000' | BFG-2 | 2 | .263" | .015" | 100',250' | ||

| BFG-16 | 16 | .053" | .010" | 100',500' | BFG-1 | 1 | .294" | .015" | 100',250' | ||

| BFG-15 | 15 | .059" | .010" | 100',500' | BFG-0 | 0 | .330" | .015" | 100',250' | ||

| BFG-14 | 14 | .066" | .013" | 100',500' | BFG-3/8" | 3/8" | .387" | .020" | 50',100' | ||

| BFG-13 | 13 | .076" | .013" | 100',500' | BFG-7/16" | 7/16" | .450" | .020" | 50',100' | ||

| BFG-12 | 12 | .085" | .013" | 100',500' | BFG-1/2" | 1/2" | .512" | .020" | 50',100' | ||

| BFG-11 | 11 | .095" | .013" | 100',500' | BFG-5/8" | 5/8" | .640" | .020" | 50',100' | ||

| BFG-10 | 10 | .106" | .013" | 100',500' | BFG-3/4" | 3/4" | .768" | .020" | 50',100' | ||

| BFG-9 | 9 | .118" | .013" | 100',250' | BFG-7/8" | 7/8" | .893" | .020" | 50',100' | ||

| BFG-8 | 8 | .133" | .013 | 100',250' | BFG-1" | 1" | 1.018" | .020" | 50',100' | ||

| BFG-7 | 7 | .148" | .015 | 100',250' |

UL RECOGNIZED FIBERGLASS SLEEVING

(.031" WALL) IS AVAILABLE TO ORDER.

SATURATED/DYED FIBERGLASS SLEEVINGS

FOR REDUCED FRAYING IS AVAILABLE TO ORDER.

BRIMFLEXä

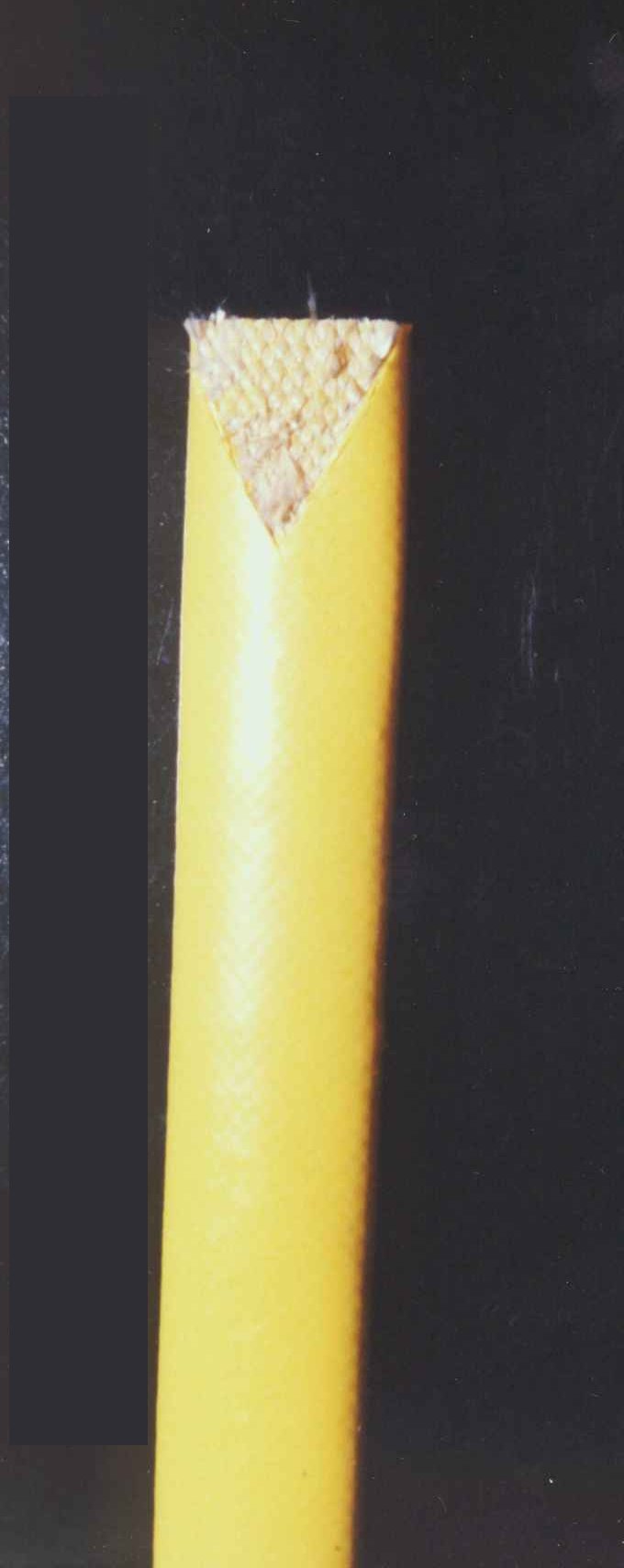

B130 VINYL COVERED FIBERGLASS SLEEVING—

MIL-I-3190/2 GRADE B-B-1 UL CLASS 130°C

BRIMFLEXä

B130 is a Vinyl covered fiberglass sleeving recommended for temperature

applica-

tions of up to +130°C.

B130 is a high temperature PVC extrusion over a heat treated inorganic

fiberglass braiding. It is very

flexible. The fiberglass is non-flammable, & the outer PVC jacket

is treated to make it heat resistant

per UL FR-1. Neither will support combustion. NEMA VSI

ASTM-D-372. Color stability retained

even after prolonged baking at elevated temperatures.

Dielectric Strength: 4000V Avg.

Meets MIL-I-3190/2 Class 130 Grade B-B-1, and UL recognized Class

130°C.

STD. COLORS: Black, Yellow. Other colors available to

order. OPER. TEMP.: -20°C

to +130°C.

| Brimlflexä No. |

Size | Nom. I.D. |

Nom. Wall |

Std. P-U | Brimlflexä No. |

Size | Nom. I.D. |

Nom. Wall |

Std. P-U | ||

| B130-24 | 24 | .022" | .015" | 100',1000' | B130-6 | 6 | .166" | .020" | 100',250' | ||

| B130-22 | 22 | .027" | .015" | 100',1000' | B130-5 | 5 | .186" | .025" | 100',250' | ||

| B130-20 | 20 | .034" | .015" | 100',1000' | B130-4 | 4 | .208" | .025" | 100',250' | ||

| B130-18 | 18 | .042" | .015" | 100',1000' | B130-3 | 3 | .234" | .025" | 100',250' | ||

| B130-17 | 17 | .047" | .015" | 100',1000' | B130-2 | 2 | .263" | .025" | 100',250' | ||

| B130-16 | 16 | .053" | .015" | 100',1000' | B130-1 | 1 | .294" | .025" | 50',100' | ||

| B130-15 | 15 | .059" | .015" | 100',500' | B130-0 | 0 | .330" | .025" | 50',100' | ||

| B130-14 | 14 | .066" | .015" | 100',500' | B130-3/8" | 3/8" | .375" | .030" | 50',100' | ||

| B130-13 | 13 | .076" | .015" | 100',500' | B130-7/16" | 7/16" | .438" | .030" | 50',100' | ||

| B130-12 | 12 | .085" | .020" | 100',500' | B130-1/2" | 1/2" | .500" | .030" | 50',100' | ||

| B130-11 | 11 | .095" | .020" | 100',500' | B130-5/8" | 5/8" | .625" | .030" | 50',100' | ||

| B130-10 | 10 | .106" | .020" | 100',500' | B130-3/4" | 3/4" | .750" | .030" | 50',100' | ||

| B130-9 | 9 | .118" | .020" | 100',500' | B130-7/8" | 7/8" | .875" | .030" | 50',100' | ||

| B130-8 | 8 | .133" | .020' | 100',500' | B130-1" | 1" | 1.000" | .030" | 50',100' | ||

| B130-7 | 7 | .148" | .020" | 100',500' |

BRIMFLEXä

B200 Silicone Rubber covered fiberglass sleeving is an excellent inorganic

high & low

temperature insulating material.

B200 provides greater mechanical strength because it is more con-

centric, homogenous and denser than

conventional dip coated Silicone Rubber Fiberglass sleeving.

The Silicone Rubber used for our B200

series is bonded to the supporting fiberglass braid so it won't

push back or peel. It is suitable

for insulation of leads and connections of electrical and electronic

components in applications requiring

high and low temperature flexibility. It is resistant to moisture,

corona, ozone, radiation, compression

set, fungus, most chemicals and solvents, weathering, flexure

fatigue and heat degradation.

Self-extinguishing (upon removal of flame per UL VW-1). The coating

maintains it's electrical integrity,

even under severe fire conditions, by forming a non-conductive ash.

Conforms to MIL-I-3190/6 Type

D Cat. C, Grade A (8000V average Dielectric Strength), & UL

recognized Class H 200°C

(available to order). OPER. TEMP.: -70°C

to +200°C.

Std. Color: White. Other colors available to order.

| Brimlflexä No. |

Size | Nom. I.D. |

Nom. Wall |

Std. P-U |

Brimlflexä No. |

Size | Nom. I.D. |

Nom. Wall |

Std. P-U |

||

| B200-24 | 24 | .022" | .030" | 1000' | B200-7 | 7 | .148" | .045" | 250' | ||

| B200-22 | 22 | .027" | .030" | 1000' | B200-6 | 6 | .166" | .045" | 250' | ||

| B200-20 | 20 | .034" | .030" | 1000' | B200-5 | 5 | .186" | .045" | 250' | ||

| B200-19 | 19 | .038" | .030" | 1000' | B200-4 | 4 | .208" | .045" | 250' | ||

| B200-18 | 18 | .042" | .030" | 1000' | B200-3 | 3 | .234" | .045" | 250' | ||

| B200-17 | 17 | .047" | .030" | 1000' | B200-2 | 2 | .263" | .055" | 250' | ||

| B200-16 | 16 | .053" | .030" | 1000' | B200-1 | 1 | .294" | .055" | 250' | ||

| B200-15 | 15 | .059" | .030" | 1000' | B200-0 | 0 | .330" | .055" | 200' | ||

| B200-14 | 14 | .066" | .045" | 500' | B200-3/8" | 3/8" | .387" | .055" | 200' | ||

| B200-13 | 13 | .076" | .045" | 500' | B200-7/16" | 7/16" | .450" | .065" | 200' | ||

| B200-12 | 12 | .085" | .045" | 500' | B200-1/2" | 1/2" | .512" | .065" | 100' | ||

| B200-11 | 11 | .095" | .045" | 500' | B200-5/8" | 5/8" | .640" | .065" | 100' | ||

| B200-10 | 10 | .106" | .045" | 500' | B200-3/4" | 3/4" | .768" | .075" | 100' | ||

| B200-9 | 9 | .118" | .045" | 500' | B200-7/8" | 7/8" | .893" | .075" | 100' | ||

| B200-8 | 8 | .133" | .045" | 500' | B200-1" | 1" | 1.018" | .075" | 100' |

BRIM

ELECTRONICS, INC. 120 HOME PLACE LODI, NJ 07644

BRIM

ELECTRONICS, INC. 120 HOME PLACE LODI, NJ 07644