BRIMFLEX™

SHRINKABLE PVC TUBINGS:

BRIMFLEX™

SHRINKABLE PVC TUBINGS:

MIL-I-23053/2B &

HEAVY WALL--SHRINKABLE

IRRADIATED

POLYOLEFIN: MIL-I-23053/5 & /4

BRIFLON™ SHRINKABLE PTFE & FEP TUBINGS

BRIMFLEX™ SHRINKABLE HEAVY WALL PVC TUBING -- UL VW-1

SHRINK RATIO: 2:1

(50%)

OPER. TEMP.: - 20°C to +105°C

SH110 meets or exceeds the

performance requirements of MIL-I-23053/2B, Class 2 but for its dimensions

-- it's heavier wall.

SH110 is a Heavy Wall Shrinkable PVC tubing, yet it's flexible, & will

shrink at temp-

eratures below 200°F

(within one minute). Provides out-standing dielectric and mechanical

protection

without damage to enclosed

or adjacent components, even around sharp bends. Longitudinal shrink-

age: approximately

20%. SH110 is self-extinguishing, resistant to fungus, moisture,

sunlight, and most

oils, and chemicals.

Dielectric Strength: 600V/MIL min., ASTM- D922. Suitable as a heavy duty

all-

purpose 600V/MIL min.,

ASTM- D922. Suitable as a heavy duty all-purpose 600V/MIL min., ASTM-

D922.

Suitable as a heavy duty

all-purpose almost as flexible, & has a higher temperature ability than

that of

Shrinkable Neoprene tubing.

|

Brimflex™

|

Min.

Exp. |

Rec.

I.D. |

Dimen.* |

± Wall |

AWG** |

Rec. |

Std. P-U |

|

SH110-1/8" |

.125" |

.063" |

.032" |

.005" |

14 |

1.59 |

1000’ |

|

SH110-3/16" |

.187" |

.093" |

.032" |

.005" |

12-10 |

2.39 |

1000’ |

|

SH110-1/4" |

.250" |

.125" |

.032" |

.005" |

8 |

3.18 |

1000’ |

|

SH110-5/16" |

.312" |

.156" |

.032" |

.005" |

6 |

3.97 |

500’ |

|

SH110-3/8" |

.375" |

.187" |

.032" |

.005" |

4 |

4.77 |

500’ |

|

SH110-1/2" |

.500" |

.250" |

.032" |

.005" |

2 |

6.35 |

500’ |

*If full recovery allowed.

**O.D. of closest equivalent wire.

RoHS compliant, & REACH Declaration & SCHV.

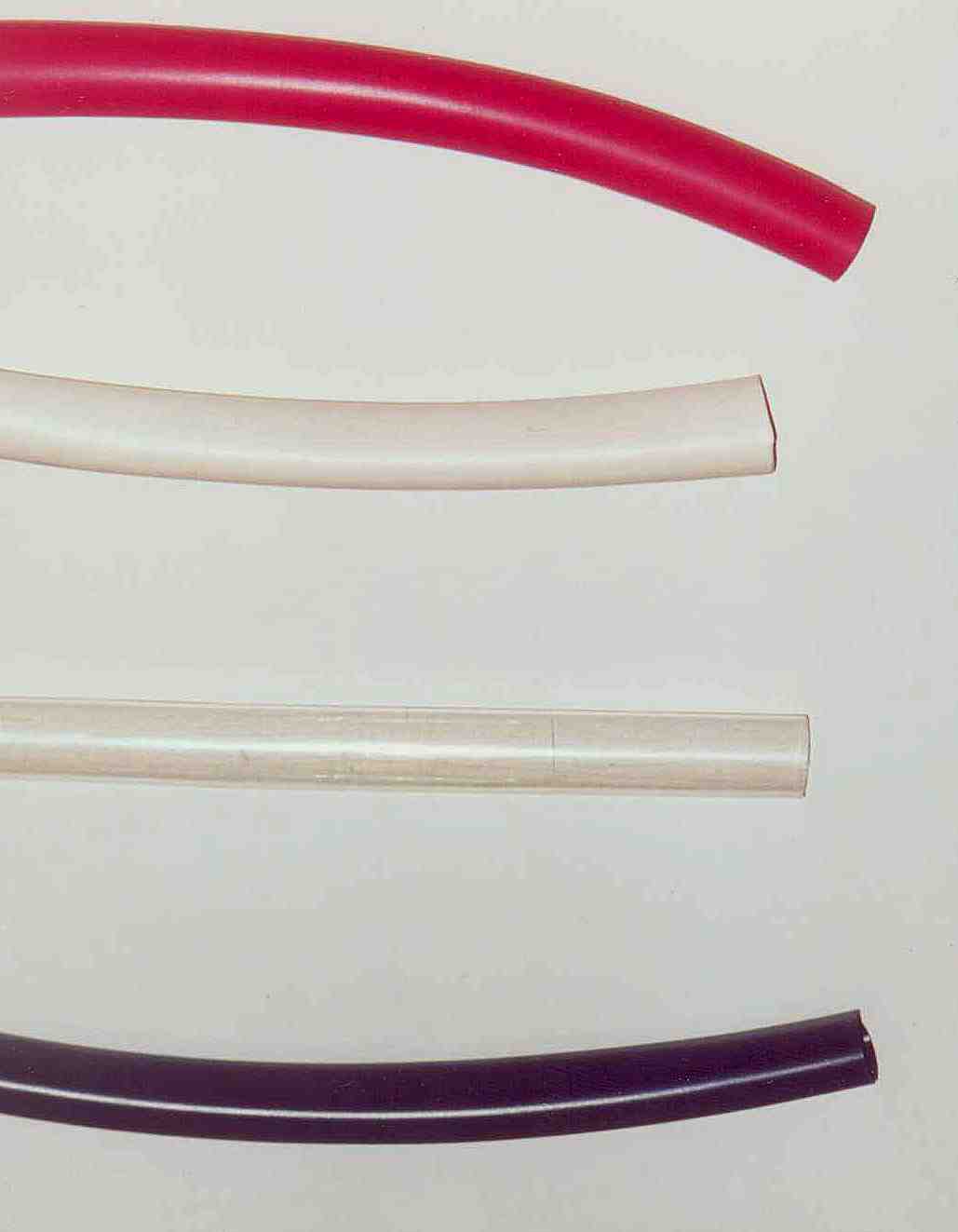

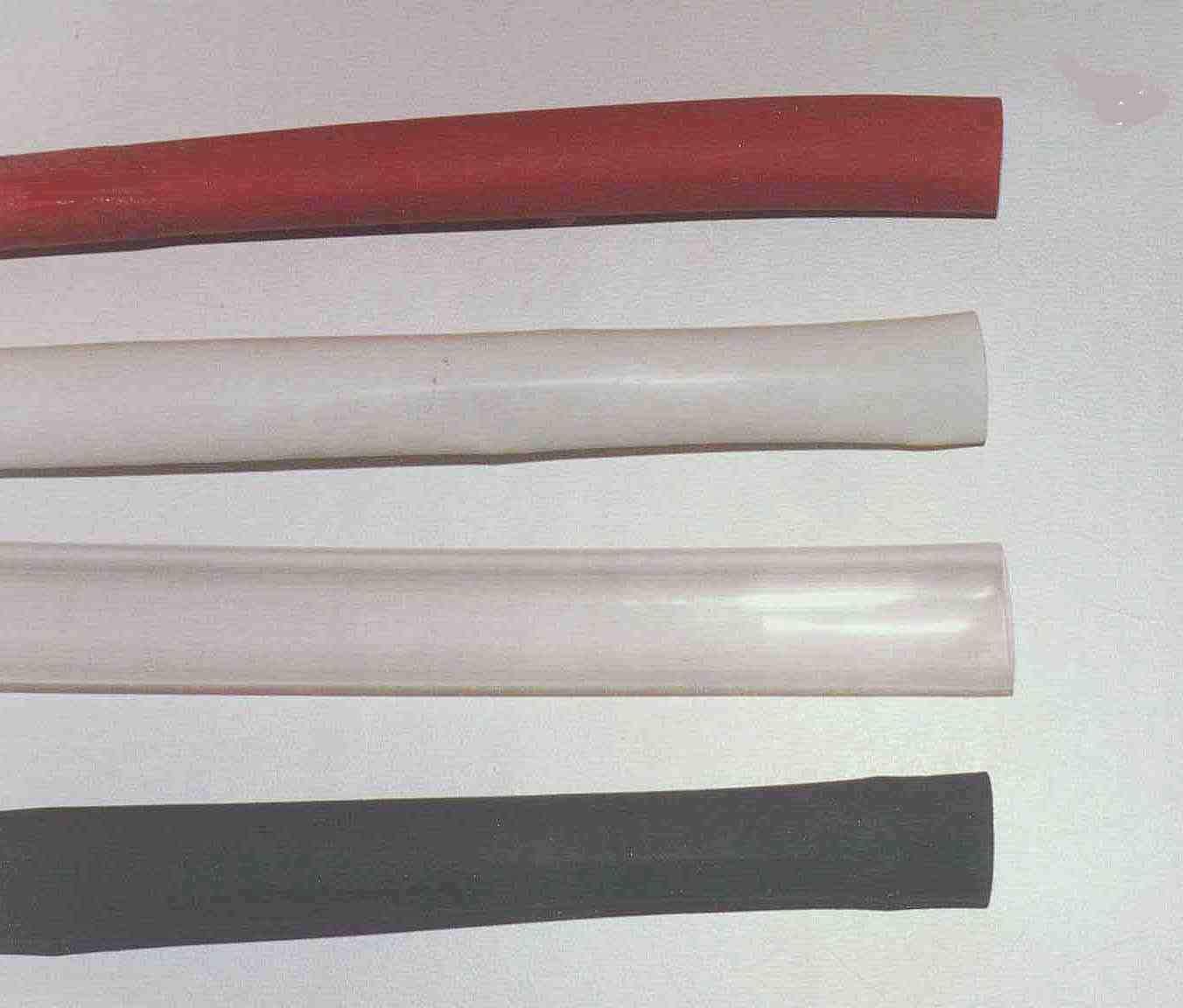

BRIMFLEX™ POLYVINYLCHLORIDE SHRINKABLE TUBING

—MIL-I-23053/2B

& UL VW-1 SHRINK RATIO: 2:1 (50%)

OPERATING TEMPERATURE: - 20°C to +105°C

BRIMFLEX™SH105 is a

flexible all purpose shrinkable PVC tubing that shrinks 50% of its expanded

size

when exposed to

temperatures below 200°F (within one minute). SH105 meets MIL-I-23053/2B,

Class 2,

and conforms to MIL-I-631D,

Grade C. Longitudinal shrinkage: approximately 20%. SH105 is self-extin-

guishing, resistant to

fungus, most oils, and chemicals, sunlight, moisture, and is non-corrosive.

SH105 is suitable for

insulating wires. cables, & electronic components, that

vary in shapes and dimensions.

Produces a smooth snug

flexible fit, in most applications -- even around sharp bends. Tensile

Strength:

2000PSImin.

Dielectric Strength: 700V/MIL min., ASTM-D922. Suggested Storage

Temperature: under

70°F for up to 10

months. UL recognized SH105 is available to order.

STD COLORS: Black, Clear (crystal clear), Red,

White. Other colors available to order.

|

Brimflex™

|

Min.

Exp. |

Rec.

I.D. |

Dimen.* |

± Wall |

AWG** |

Rec. |

Std. P-U |

|

SH105-3/64" |

.046" |

.023" |

.020" |

.003" |

24-22 |

0.59 |

---- ,---- , 1000' |

|

SH105-1/16" |

.063" |

.031" |

.020" |

.003" |

22-20 |

0.80 |

100',500',1000' |

|

SH105-3/32" |

.093" |

.046" |

.025" |

.003" |

18-16 |

1.19 |

100',500',1000' |

|

SH105-1/8" |

.125" |

.063" |

.025" |

.003" |

14 |

1.59 |

100',500',1000' |

|

SH105-3/16" |

.187" |

.093" |

.025" |

.003" |

12-10 |

2.39 |

100',500',1000' |

|

SH105-1/4" |

.250" |

.125" |

.025" |

.005" |

8 |

3.18 |

100',500',1000' |

|

SH105-5/16" |

.312" |

.156" |

.028" |

.005" |

7 |

3.97 |

100',500',1000' |

|

SH105-3/8" |

.375" |

.187" |

.028" |

.005" |

5 |

4.77 |

100',500',1000' |

|

SH105-1/2" |

.500" |

.250" |

.028" |

.005" |

2 |

6.35 |

100',250',500' |

|

SH105-5/8" |

.625" |

.312" |

.033" |

.005" |

1 |

7.93 |

100',250',500' |

|

SH105-3/4" |

.750" |

.375" |

.033" |

.005" |

00 |

9.52 |

100',250',500’ |

|

SH105-1" |

1.000" |

.500" |

.038" |

.005" |

0000 |

12.70 |

100',250',500’ |

|

SH105-1 1/4" |

1.250" |

.625" |

.040" |

.005" |

300MCM |

15.88 |

100',250',500’ |

|

SH105-1 1/2" |

1.500" |

.750" |

.043" |

.005" |

450MCM |

19.05 |

---- , 50',100' |

|

SH105-2" |

2.000" |

1.000" |

.048" |

.006" |

750MCM |

25.40 |

---- , 50',100' |

|

SH105-2 1/2" |

2.500" |

1.250" |

.058" |

.007" |

1250MCM |

31.75 |

---- ,----,100' |

|

SH105-3" |

3.000" |

1.500" |

.068" |

.007" |

1750MCM |

38.10 |

---- ,----,100' |

|

SH105-4" |

4.000" |

2.000" |

.073" |

.008" |

2750MCM |

50.95 |

---- ,----',100' |

* If full recovery

allowed. ** O.D. of closest equivalent wire.

RoHS compliant, & REACH Declaration & SCHV.

SHRINKABLE IRRADIATED POLYOLEFIN TUBING

-- ALL PURPOSE -- MIL-I-23053/5A

SH135 is flexible yet it

provides greater electrical, chemical, and abrasion resistance and greater

mech-

anical strength than that

of shrinkable PVC tubing. It not only insulates, it can also encapsulate

giving

a watertight

fit. Won't crack or peel. It's non-corrosive, has excellent

resistance to soldering irons, oils,

solvents, acids, alkalis,

fuels, hydraulic fluids, and fungus. Shrink Ratio--2:1 (50%).

Shrinks when

exposed to 250°F.

Longitudinal shrinkage: 5%. Dielectric Strength: 1300V/MIL. Colored

tubing is self-

extinguishing; clear tubing

is slow burning. OPER. TEMP.: -55°C to +135°C. Uses: Strain relief,

jacket-

ing material, component

insulation. Meets MIL-I-23053/5A, Class 1,2 MIL-I-7444B, AMS 3636B,

AMS 3637A, ASTM D876, ASTM

D150, ASTM D257,ASTM D2671, ASTM D792.

|

Brimflex™ |

Min. Exp. |

Rec. I.D. |

Dimen.* |

± Wall |

AWG** |

Rec. |

STD. P-U |

|

SH135-3/64" |

.046" |

.023" |

.016" |

.003" |

22 |

0.59 |

100',500',1000' |

|

SH135-1/16" |

.063" |

.031" |

.016" |

.003" |

22-20 |

0.80 |

100',500',1000' |

|

SH135-3/32" |

.093" |

.046" |

.020" |

.003" |

18-16 |

1.19 |

100',500',1000' |

|

SH135-1/8" |

.125" |

.063" |

.020" |

.003" |

14 |

1.59 |

100',500',1000' |

|

SH135-3/16" |

.187" |

.093" |

.020" |

.003" |

12-10 |

2.39 |

100',500',1000' |

|

SH135-1/4" |

.250" |

.125" |

.025" |

.003" |

8 |

3.18 |

100',250', 500' |

|

SH135-3/8" |

.375" |

.187" |

.025" |

.003" |

5 |

4.77 |

50',100', 200' |

|

SH135-1/2" |

.500" |

.250" |

.025" |

.003" |

2 |

6.35 |

50',100', 200' |

|

SH135-3/4" |

.750" |

.375" |

.030" |

.005" |

00 |

9.52 |

25', 50',100' |

|

SH135-1" |

1.000" |

.500" |

.035" |

.006" |

0000 |

12.70 |

25', 50',100' |

|

SH135-1 1/2" |

1.500" |

.750" |

.040" |

.006" |

450MCM |

19.05 |

25', 50',100' |

|

SH135-2" |

2.000'' |

1.000" |

.045" |

.007" |

750MCM |

25.40 |

25', 50',100' |

|

SH135-3" |

3.000" |

1.500" |

.050" |

.008" |

1750MCM |

38.10 |

25', 50',100' |

|

SH135-4" |

4.000" |

2.000'' |

.055" |

.009" |

2750MCM |

50.80 |

25', 50',100' |

STD. COLORS: Black, Clear, Red, White. Other colors are available to order.

*If full recovery allowed. **O.D. of closest equivalent wire. RoHS compliant.

SEMI-RIGID IRRADIATED POLYOLEFIN

SHRINKABLE TUBING IS AVAILABLE TO ORDER.

CUT & PRINTED WIRE MARKERS ARE AVAILABLE

TO ORDER.

4:1 SHRINKABLE IRRADIATED POLYOLEFIN TUBING

(NEW)

-- DUAL-WALLED -- MIL-I-23053/4

SH134 is very flexible yet

it provides greater electrical, chemical, and abrasion resistance & greater

mechanical strength than that of shrinkable PVC tubing, plus an inner wall of

meltable liner. With it's

meltable inner/adhesive liner it not only insulates, it can also encapsulate

giving a watertight fit.

Won't crack or peel. It's non-corrosive, has excellent resistance to

soldering irons, oils, solvents, acids,

alkalis, fuels, hydraulic fluids, and fungus, and it's flame

retardant. Shrink Ratio--4:1 (75%). Shrinkage

begins when exposed to 120°C. Longitudinal shrinkage: 10%.

Dielectric Strength: 400V/Mil min.

Uses: Strain reliefs, jacketing material, component insulation, seal and

protect wire splices, breakouts

or connectors-to-cable terminations. OPER. TEMP.: -55°C to +135°C.

Meets MIL-I-23053/4, Class 3, UL VW-1, CSA OFT (jacket only), ASTM D638.

|

|

||||||

|

Brimflex™ |

Min. Exp. |

Rec. I.D. |

Rec. I.D. |

Thick. |

Thick. |

Std. |

|

SH134-3/16" |

.158" |

.039" |

1.0 |

.035" |

.020" |

100' |

|

SH134-5/16" |

.315" |

.079" |

2.0 |

.035" |

.020" |

100' |

|

SH134-1/2" |

.472" |

.118" |

3.0 |

.051" |

.024" |

100' |

|

SH134-3/4" |

.630" |

.157" |

4.0 |

.063" |

.030" |

100' |

|

SH134-1" |

.945" |

.236" |

5.0 |

.083" |

.031" |

100' |

|

SH134-1 1/4" |

1.260" |

.315" |

6.0 |

.091" |

.041" |

100' |

STD. COLOR: Black

STD. P-U: 4ft. lengths.

*Total wall thickness including liner, if full recovery allowed.

**Total wall thickness of liner only, if full recovery allowed.

++O.D. of closest equivalent wire. RoHS compliant.

SH200,

SH250, SH254 and SHTF tubings have excellent resistance to weathering,

chemicals (oils, fuels,

solvents, acids, alkalis, fluids), and fungus, are non-corrosive, low water

absorption (.01%), will not

burn nor support combustion, have high dielectric strength (850V/MIL dry), low

dielectric constant, and

a very low coefficient of friction. High mechanical strength yet flexible

(low temperature flexibility

-67°C). Color: Natural (FEP-transparent;

PTFE-translucent). Their excellent electrical characteristics

remain stable throughout their electrical range.

Longitudinal change with full shrinkage: FEP - 15%: TFE - 20%.

BRIFLON™ SHTF SHRINKABLE PTFE/FEP

SHTF is made with a

combination of PTFE and FEP resins. The inner wall is made of FEP &

the outer

wall of PTFE. When

the tubing is heated, the PTFE begins to shrink down tightly over the

FEP. The FEP

inner wall melts and flows

-squeezes- into

and around the item covered, creating a solid or near solid

encapsulation. The

fit is so tight that it is safe against most environmental hazards involving

pull or

vibrations. It can be

used as a strain relief, or moisture-proof covering for wires, connectors,

terminals,

splices, electronic

devices, etc. SHTF is non-flammable, non-corrosive, and offers all

of the other

outstanding electrical

chemical, and mechanical properties of Teflon*. OPER. TEMP.: -85°F to

+450°F

|

Briflon™ |

Min.

Exp. |

Max.

Rec. |

Dimen. |

|

Briflon™ |

Min.

Exp. |

Max.

Rec. |

Dimen. |

|

SHTF-1 |

.065" |

.000"** |

.015" |

|

SHTF-6 |

.240" |

.150" |

.020" |

|

SHTF-2 |

.115" |

.045" |

.015" |

|

SHTF-7 |

.350" |

.210" |

.025" |

|

SHTF-3 |

.130" |

.060" |

.015" |

|

SHTF-8 |

.480" |

.315" |

.032" |

|

SHTF-4 |

.180" |

.065" |

.015" |

|

SHTF-9 |

.700" |

.440" |

.040" |

|

SHTF-5 |

.190" |

.070" |

.015" |

|

SHTF-10 |

1.000" |

.700" |

.045" |

STD. P-U: 100ft.

(In random lengths of 1Ft. to 3 Ft.) ** Fully closes off.

*DuPont

RoHS compliant.

BRIFLON™ SH200 (SHRINKABLE FEP) 1.3:1 MIL-I-23053/11 200°C

SH200: an extruded modified

FEP (Fluorinated-Ethylene-Propylene) tubing, with a continuous

Oper. Temp. of +205°C

(400°F). SH200 completely shrinks at 384°F (partial shrinkage possible

at 300°F). Shrinkage ratio -- 1.3:1. It melts at 525-563°F so it

can be used to encapsulate.

Now many sensitive components, parts, devices, etc. can be protected with

FEP.

Fills void between the high temperature of PTFE, and the low temperature of

shrinkable PVC

and Polyolefin

tubings. STD. P-U: 100', 4ft. min. lengths.

|

Briflon™ |

Min. |

Max. |

Dimen. |

± Wall |

|

Briflon™

|

Min. |

Max. |

Dimen. |

± Wall |

|

SH200-24 |

.031" |

.027" |

.008" |

.002" |

|

SH200-3 |

.310" |

.249" |

.011" |

.004" |

|

SH200-22 |

.036" |

.032" |

.008" |

.002" |

|

SH200-2 |

.365" |

.280" |

.012" |

.004" |

|

SH200-20 |

.045" |

.039" |

.008" |

.002" |

|

SH200-1 |

.400" |

.311" |

.012" |

.004" |

|

SH200-18 |

.060" |

.049" |

.008" |

.002" |

|

SH200-0 |

.440" |

.349" |

.012" |

.004" |

|

SH200-16 |

.075" |

.061" |

.009" |

.002" |

|

SH200-3/8" |

.500" |

.383" |

.015" |

.004" |

|

SH200-14 |

.092" |

.072" |

.009" |

.002" |

|

SH200-7/16" |

.580" |

.448" |

.020" |

.004" |

|

SH200-12 |

.115" |

.089" |

.009" |

.002" |

|

SH200-1/2" |

.666" |

.510" |

.020" |

.004" |

|

SH200-10 |

.141" |

.114" |

.010" |

.003" |

|

SH200-5/8" |

.830" |

.637" |

.025" |

.004" |

|

SH200-9 |

.158" |

.124" |

.010" |

.003" |

|

SH200-3/4" |

1.000" |

.764" |

.030" |

.004" |

|

SH200-8 |

.180" |

.143" |

.010" |

.003" |

|

SH200-7/8" |

1.170" |

.891" |

.035" |

.004" |

|

SH200-7 |

.197" |

.158" |

.011" |

.004" |

|

SH200-1" |

1.330" |

1.020" |

.035" |

.004" |

|

SH200-6 |

.225" |

.180" |

.011" |

.004" |

|

SH200-1 1/4" |

1.660" |

1.270" |

.035" |

.004" |

|

SH200-5 |

.248" |

.198" |

.011" |

.004" |

|

SH200-1 1/2" |

2.000" |

1.520" |

.035" |

.004" |

|

SH200-4 |

.290" |

.226" |

.011" |

.004" |

|

|

|

|

|

|

** All dimensions are based on full recovery. RoHS compliant.

BRIFLON™ SH206 (SHRINKABLE FEP) 1.6:1 MIL-I-23053/11 200°C

SH206 tubings are

extruded modified FEP (Fluorinated-Ethylene-Propylene) tubing, with a

continuous

Oper. Temp. of +205°C

(400°F). SH206 can completely shrink at 384°F with partial

shrinkage as low as

350°F. Shrinkage

ratio -- 1.6:1. Suitable for those applications where 1.6:1 shrink

capabilities are

required and standard 1.3:1

shrink FEP is not sufficient. It melts at 525-563°F so it can be used to

encapsulate. Now many

sensitive components, parts, devices, etc. can be protected with

FEP. Fills

the void between the high

temperature of PTFE, and the low temperature of shrinkable PVC and Polyolefin

tubings. Mfg. per

MIL-I-23053/11 Cl.2. STD. COLOR: Natural (Transparent).

|

Briflon™

|

Min. |

Max. |

Dimen. |

± Wall |

STD. |

|

Briflon™ |

Min. |

Max. |

Dimen. |

± Wall |

STD. |

|

SH206-3/32" |

.093" |

.056" |

.008" |

.003" |

100' |

|

SH206-1/2" |

.500" |

.300" |

.015" |

.004" |

100' |

|

SH206-1/8" |

.125" |

.075" |

.010" |

.003" |

100' |

|

SH206-3/4" |

.750" |

.450" |

.020" |

.004" |

100' |

|

SH206-3/16" |

.188" |

.115" |

.010" |

.003" |

100' |

|

SH206-1" |

1.000" |

.600" |

.025" |

.005" |

50' |

|

SH206-1/4" |

.250" |

.150" |

.010" |

.003" |

100' |

|

SH206-1 1/2" |

1.500" |

.900" |

.030" |

.005" |

50' |

|

SH206-3/8" |

.375" |

.225" |

.012" |

.003" |

100' |

|

SH206-2" |

2.000" |

1.200" |

.030" |

.005" |

50' |

*4ft. min.

lengths. RoHS compliant.

OTHER SIZES AND

COLORS AVAILABLE TO ORDER

ETCHING FOR BONDING IS AVAILABLE TO ORDER.

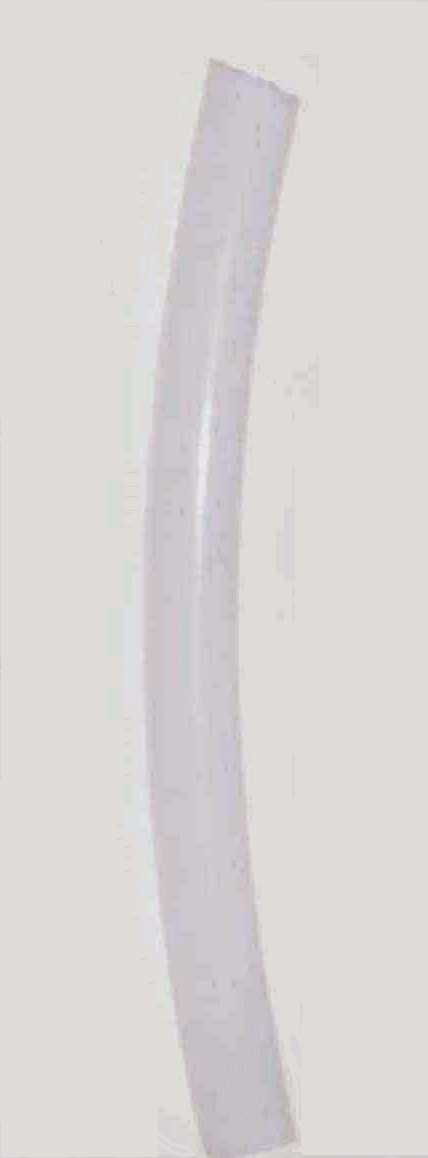

BRIFLONä SH250 (SHRINKABLE PTFE)

1.5:1 MIL-I-23053/12 250°C

SH250: an extruded

modified PTFE (PolyTetraFluoroEthylene) tubing, with a continuous operating

temperature of +250°C

(550°F). SH250 will shrink when heated to 621°F. Shrinkage ratio —

1.5:1.

Used wherever

hi-temperature protection required. Applications: Protective covers in

corrosive

environments, protection

for electronic components, cable jacketing covers on immersion heaters,

heat exchangers, light duty

bearing surfaces, roll covers. MIL-I-23053/12 Class 2** or Class 3,

MIL-DTL-23053/12,

AMS-DTL-23053/12, STD.P-U:

100', Sizes 30-14: 3ft. min., 13-1" 1ft. min. lgths.

|

Briflon™ |

Min. |

Max. |

Dimen. |

± Wall |

|

Briflon™

|

Min. |

Max. |

Dimen. |

± Wall |

|

SH250-30 |

.034" |

.015" |

.009" |

.002" |

|

SH250-9 |

.205" |

.124" |

.015" |

.004" |

|

SH250-28 |

.038" |

.018" |

.009" |

.002" |

|

SH250-8 |

.240" |

.141" |

.015" |

.004" |

|

SH250-26 |

.046" |

.022" |

.010" |

.002" |

|

SH250-7 |

.270" |

.158" |

.015" |

.004" |

|

SH250-24 |

.050" |

.027" |

.010" |

.002" |

|

SH250-6 |

.302" |

.178" |

.015" |

.004" |

|

SH250-22 |

.055" |

.032" |

.012" |

.003" |

|

SH250-5 |

.320" |

.198" |

.015" |

.004" |

|

SH250-20 |

.060" |

.039" |

.012" |

.003" |

|

SH250-4 |

.370" |

.224" |

.015" |

.004" |

|

SH250-19 |

.065" |

.043" |

.012" |

.003" |

|

SH250-3 |

.390" |

.249" |

.015" |

.004" |

|

SH250-18 |

.076" |

.049" |

.012" |

.003" |

|

SH250-2 |

.430" |

.278" |

.015" |

.004" |

|

SH250-17 |

.085" |

.054" |

.012" |

.003" |

|

SH250-1 |

.450" |

.311" |

.015" |

.004" |

|

SH250-16 |

.093" |

.061" |

.012" |

.003" |

|

SH250-0 |

.470" |

.347" |

.015" |

.004" |

|

SH250-15 |

.110" |

.067" |

.012" |

.003" |

|

SH250-3/8"** |

.560" |

.399" |

.025" |

.006" |

|

SH250-14 |

.120" |

.072" |

.012" |

.003" |

|

SH250-1/2"** |

.750" |

.524" |

.025" |

.006" |

|

SH250-13 |

.140" |

.080" |

.012" |

.003" |

|

SH250-5/8"** |

.930" |

.655" |

.030" |

.006" |

|

SH250-12 |

.150" |

.089" |

.012" |

.003" |

|

SH250-3/4"** |

1.125" |

.786" |

.035" |

.008" |

|

SH250-11 |

.170" |

.101" |

.012" |

.003" |

|

SH250-1"** |

1.500" |

1.036" |

.035" |

.008" |

|

SH250-10 |

.191" |

.112" |

.012" |

.003" |

|

|

|

|

|

|

**BASED ON FULL RECOVERY. ETCHING FOR BONDING IS AVAILABLE TO ORDER.

BRIFLONä SH254 4:1 (SHRINKABLE PTFE) MIL-I-2053/12 250°C

SH254 tubing can recover

to approximately 1/4 of its expanded size when heated to its gel-point (621°F

-625°F). Because

of its exceptional shrinkage capability, its recommended that the outside

diameter

of the object to be shrunk

upon down should not be more than 50% of the expanded I.D. of the size of

the tubing used. Many

sizes conform to AMS 3584 and MIL-I-23053/12 Cl.5, MIL-DTL-23053/12,

AMS-DTL-23053/12 SH254 is non-flamable, non-corrosive, and offers all of the

other outstanding electrical,

chemical, and mechanical properties of PTFE. Std. Color: Natural (Clear) .

|

Briflon™

|

Min. |

Min. |

Dimen. |

± Wall |

|

Briflon™

|

Min. |

Min. |

Dimen. |

± Wall |

|

SH254-5/64"+ |

.078" |

.025" |

.009" |

.002" |

|

SH254-9/16" |

.562" |

.155" |

.015" |

.004" |

|

SH254-1/8"+ |

.125" |

.037" |

.010" |

.002" |

|

SH254-5/8"+ |

.625" |

.178" |

.015" |

.004" |

|

SH254-3/16" |

.187" |

.050" |

.012" |

.003" |

|

SH254-11/16" |

.687" |

.198" |

.015" |

.004" |

|

SH254-1/4"+ |

.250" |

.063" |

.012" |

.003" |

|

SH254-3/4"+ |

.750" |

.224" |

.015" |

.004" |

|

SH254-5/16" |

.312" |

.079" |

.012" |

.003" |

|

SH254-7/8" |

.875" |

.244" |

.015" |

.004" |

|

SH254-3/8"+ |

.375" |

.096" |

.012" |

.003" |

|

SH254-1"+ |

1.000" |

.278" |

.015" |

.004" |

|

SH254-7/16" |

.438" |

.112" |

.012" |

.003" |

|

SH254-1 1/4"+ |

1.250" |

.347" |

.015" |

.004" |

|

SH254-1/2"+ |

.500" |

.144" |

.015" |

.004" |

|

|

|

|

|

|

STD. P-U: 100', in 4 ft.

min. lengths. **Based on full recovery. +Per MIL-I-23053/12A Class

5.

RoHS compliant.

OTHER SIZES & COLORS IN TFE

AND FEP ARE AVAILABLE TO ORDER.

ETCHING FOR BONDING IS AVAILABLE TO

ORDER.

BRIM ELECTRONICS, INC. 120

HOME PLACE LODI, NJ 07644

BRIM ELECTRONICS, INC. 120

HOME PLACE LODI, NJ 07644

TEL: 201-796-2886

FAX: 973-778-2792 E-MAIL: info@brimelectronics.com